MESenz

Manufacturing Execution System (MES)

MES (Manufacturing Execution System)

is a real-time production control and monitoring system for factories. It seamlessly integrates with ERP and machinery systems, helping your factory reduce waste, lower costs, and boost production efficiency.

MESenz was built to fulfill the true potential of

Manufacturing Execution Systems (MES).

It empowers your business

TO RISE TO THE TOP

— through smarter production that drives peak efficiency.

In the world of industry,

Precision and Efficiency are

THE HEARTBEAT OF SUCCESS

What Can MESenz Do for You?

Real-time visibility into production status.

Accurately track waste quantities and identify root causes.

Reduce reporting time and enhance accuracy

Seamlessly connects with ERP systems and automated machinery.

MESenz Feature

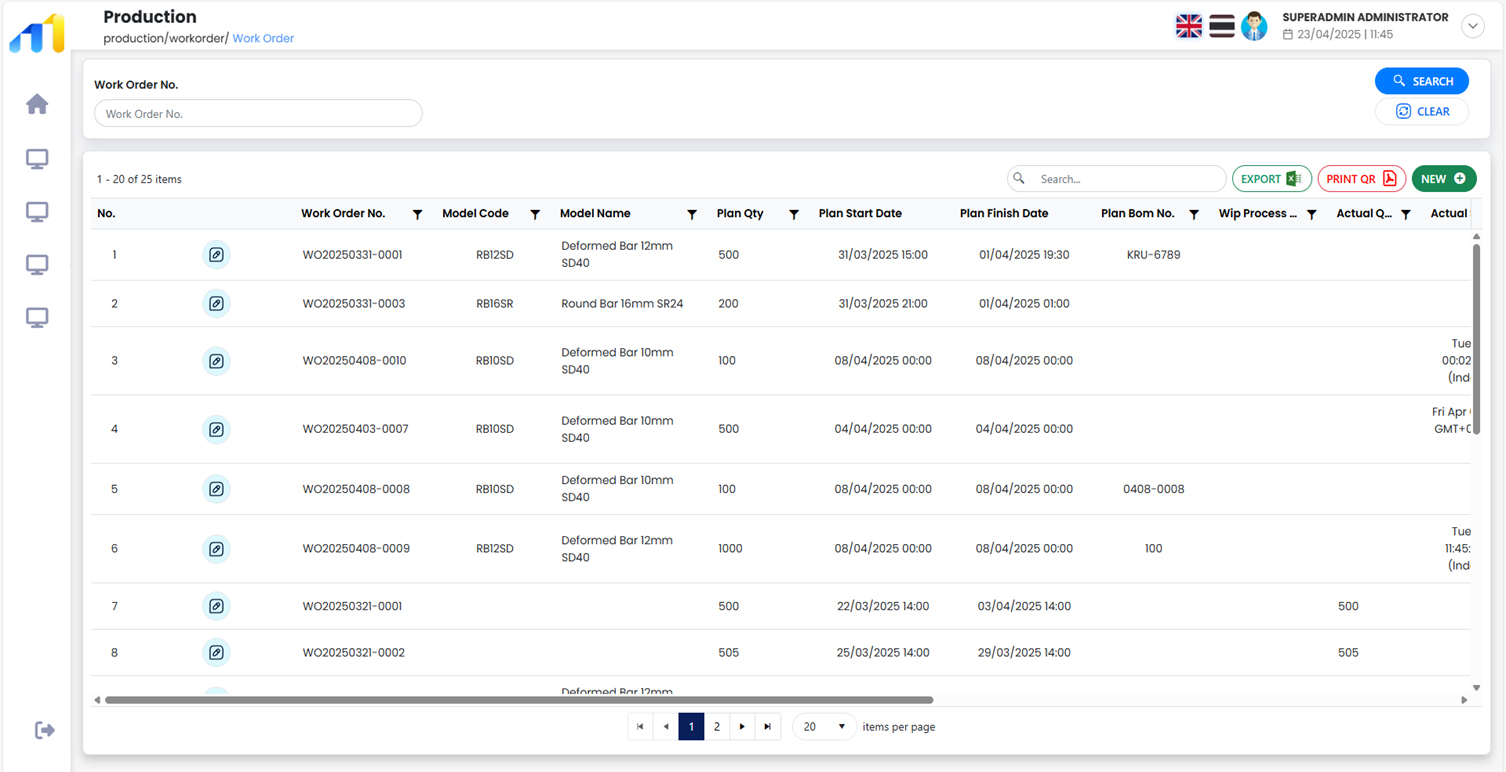

1 Production Plan

- Supports production planning directly from ERP systems.

- Adapt production plans in response to real-world conditions

2 Data Collection

- Data entry from operators via screens and mobile devices.

- Record production time, downtime, and maintenance activities.

3 Quality Result

- Record good and defective outputs with the reasons

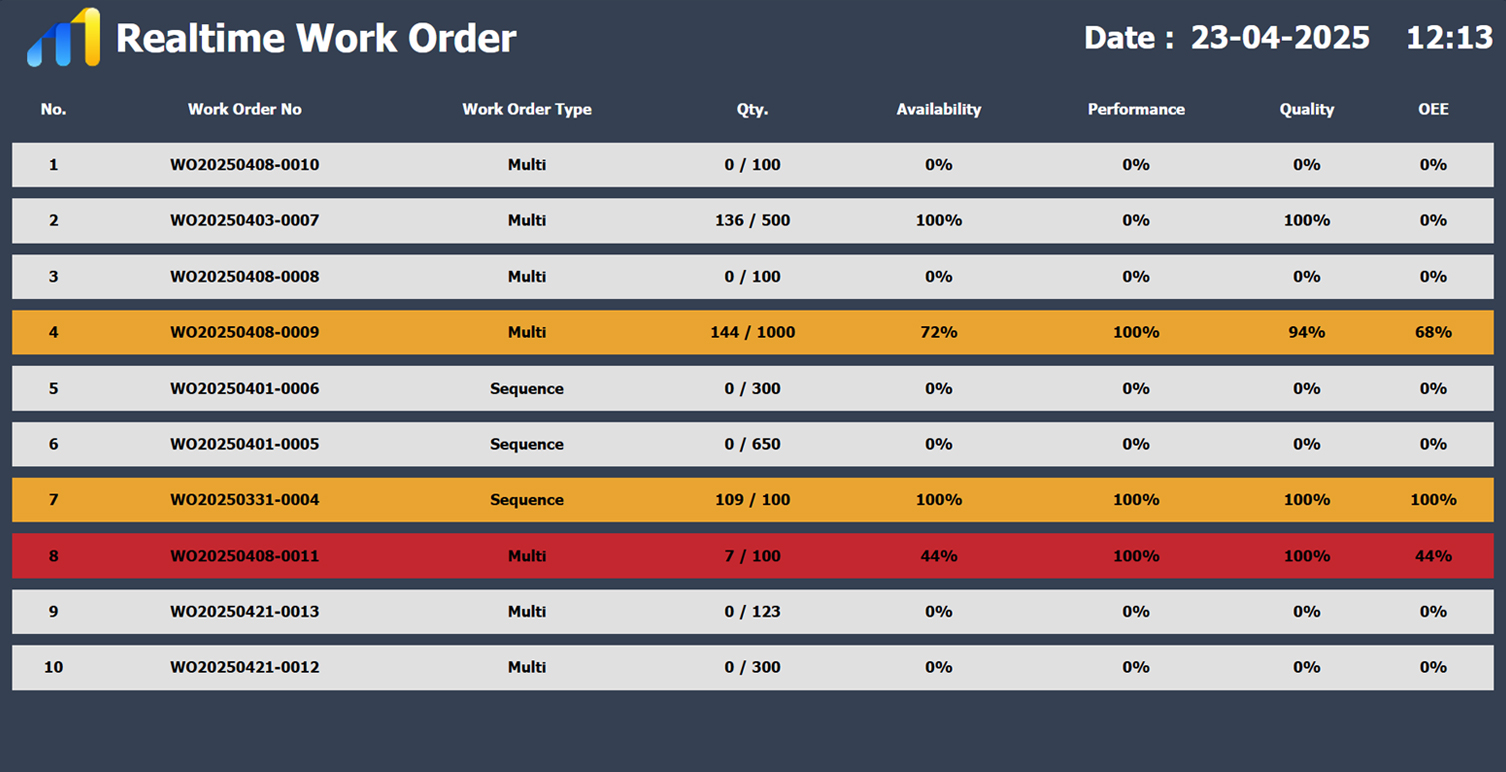

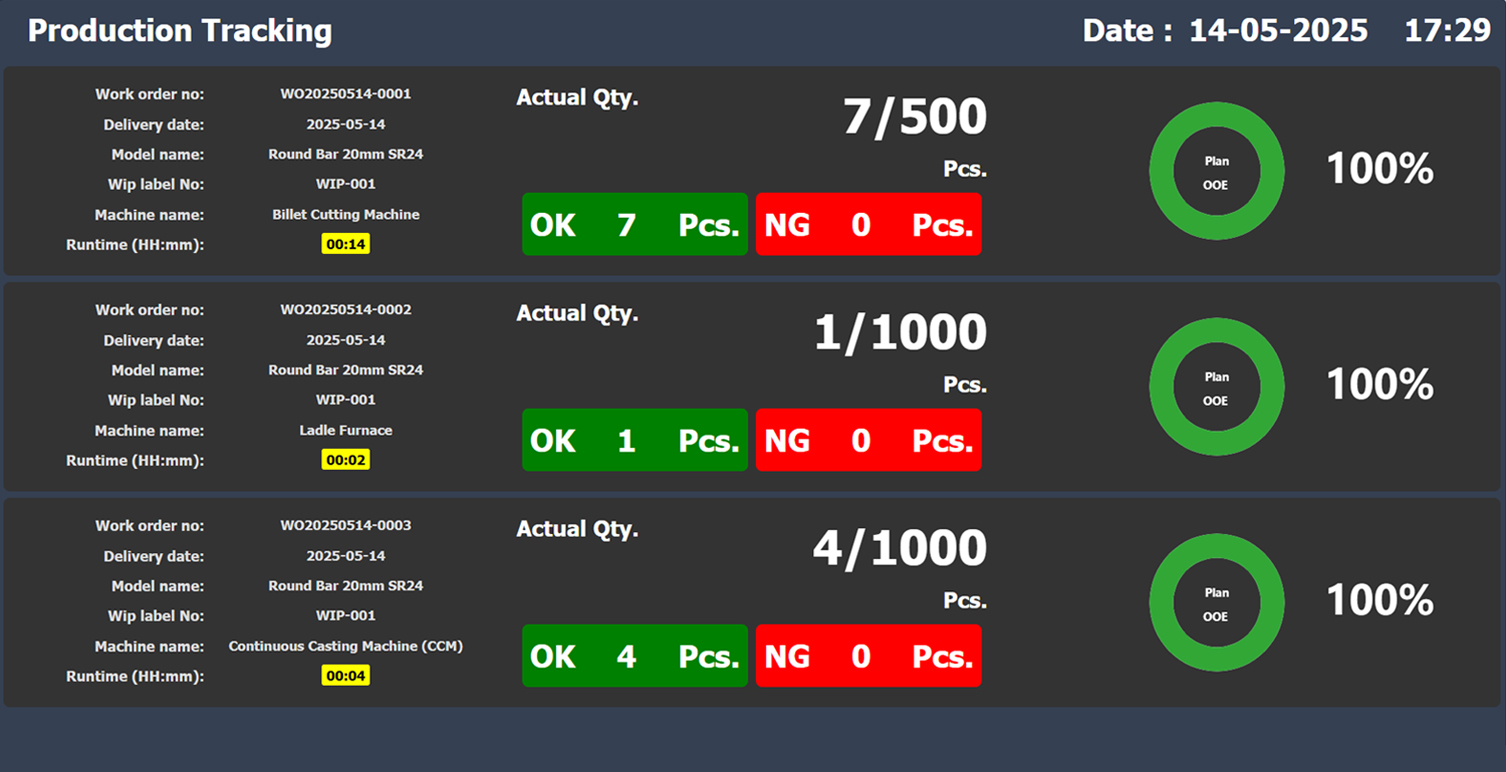

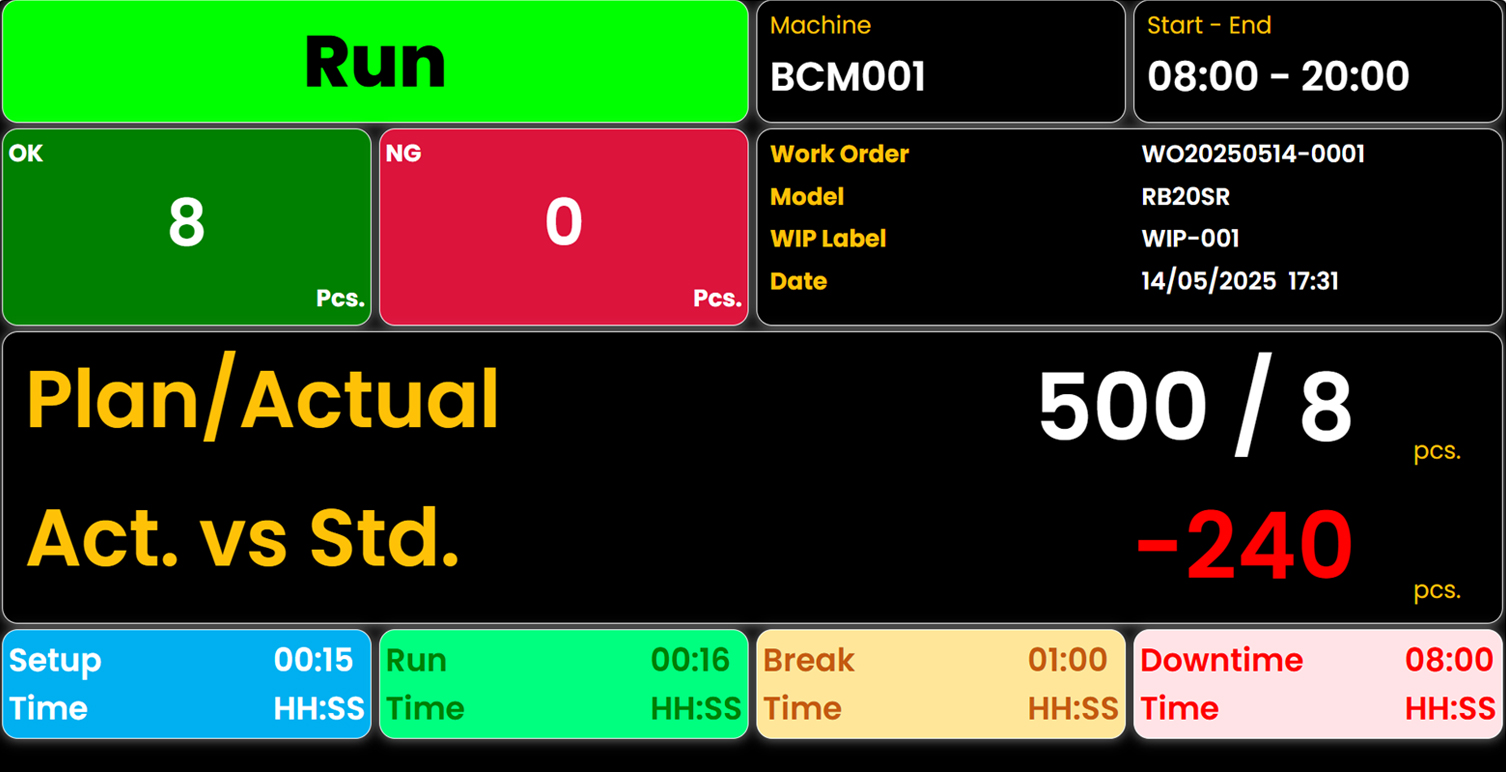

4 Production & Machine Monitoring

- Display production results according to the plan

- Display real-time information of production orders

- Display real-time machine status

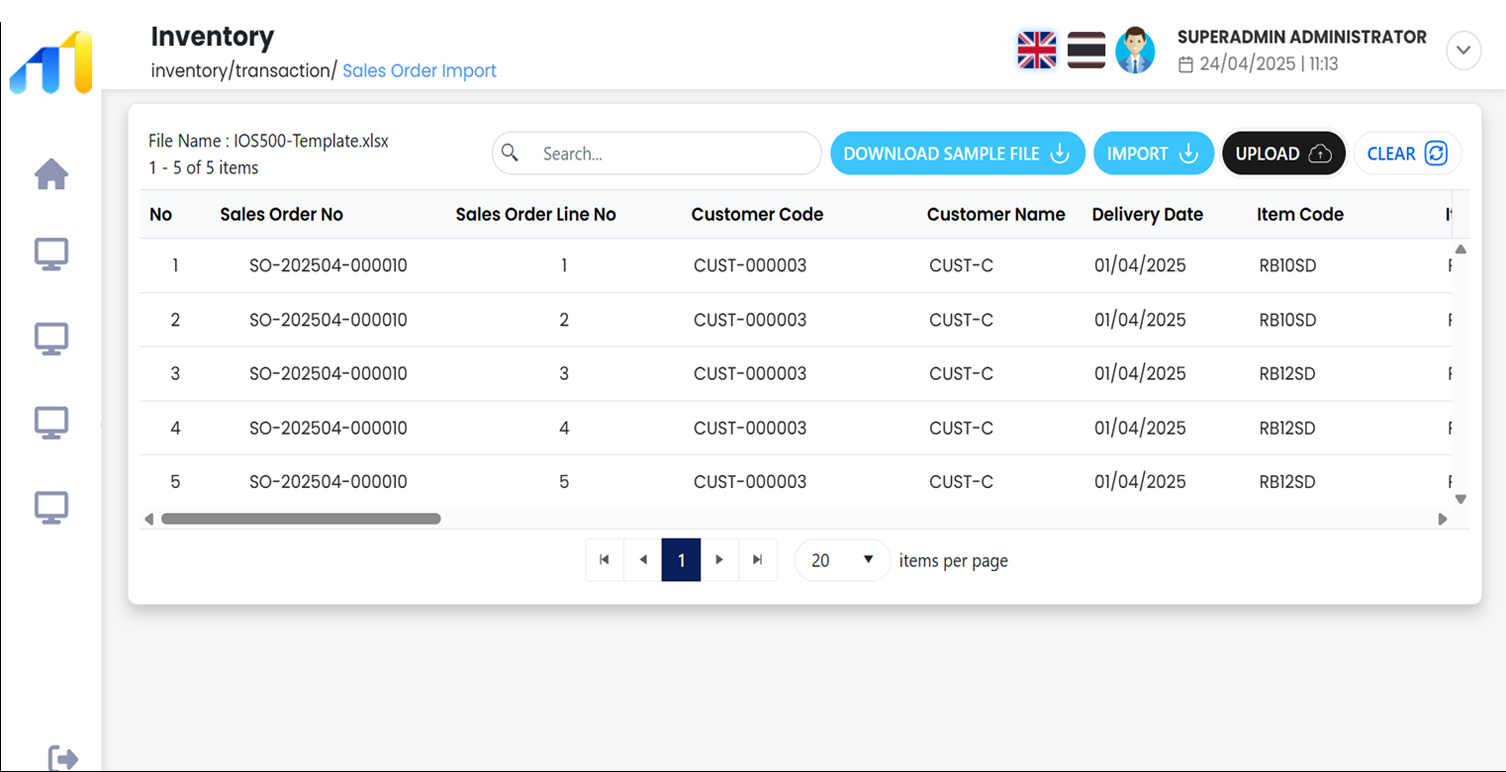

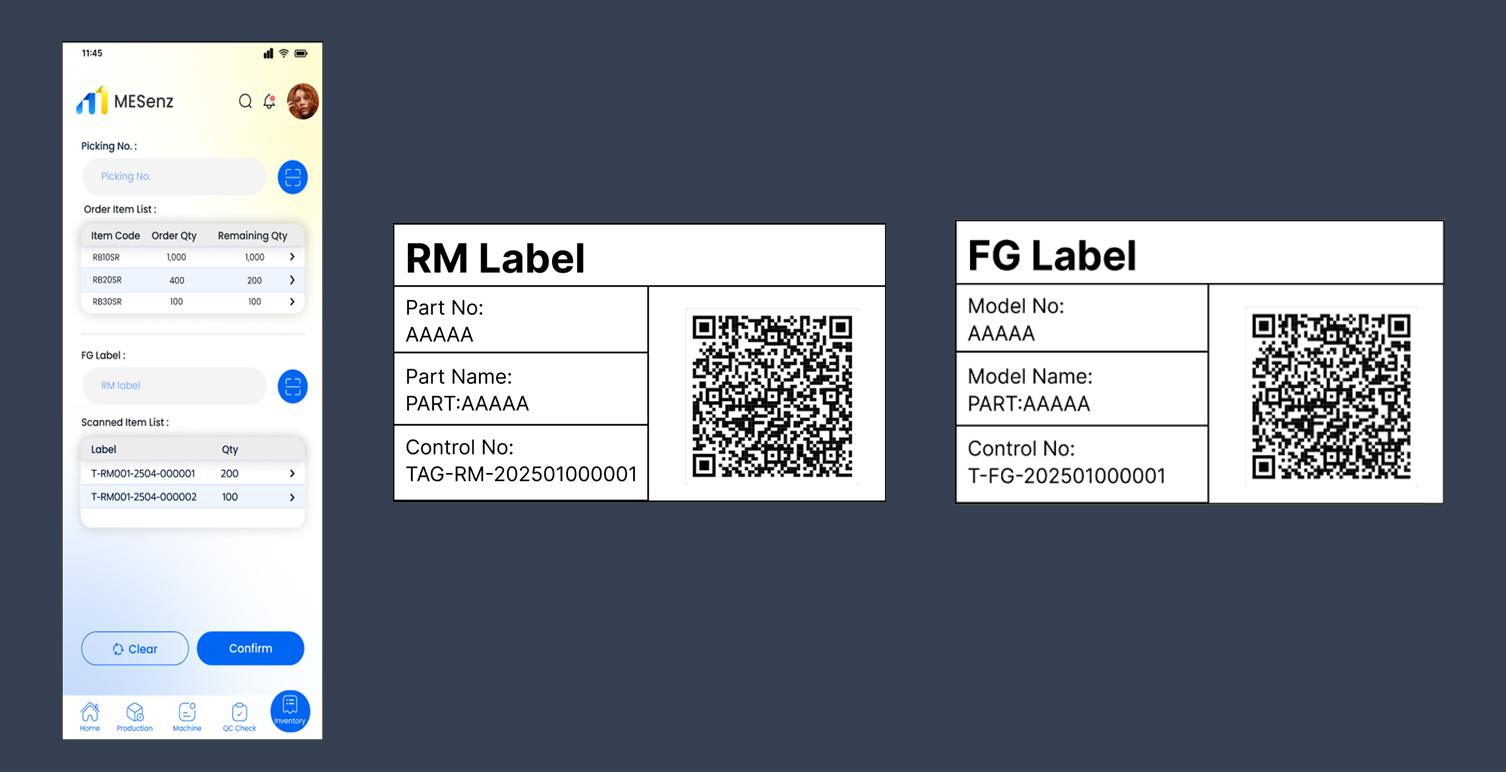

5 RM receiving and shipping

- Receive raw materials and apply labeling to ensure accurate usage

- Confirm delivery items to minimize shipping errors

6 Machine Maintenance

- Plan maintenance activities proactively and efficiently

- Log maintenance results with photo attachments for enhanced traceability and accuracy